Factory For Pulverized Coal Fired Boiler Pdf – CFB Coal Fired Boiler – Taishan Group

Factory For Pulverized Coal Fired Boiler Pdf – CFB Coal Fired Boiler – Taishan Group Detail:

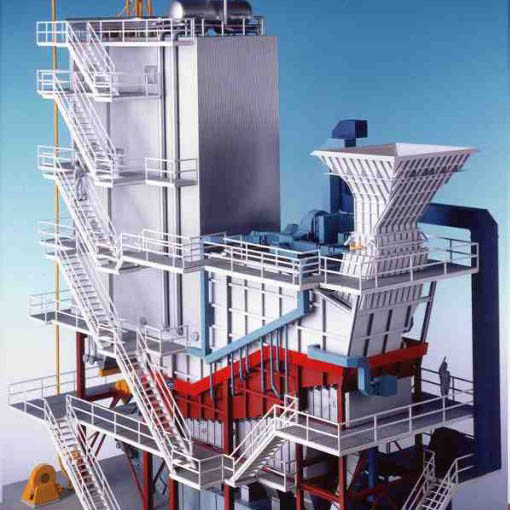

CFB Coal Fired Boiler

Product Description

CFB boiler (Circulating Fluidized Bed Boiler) features good coal adaptation, safe and reliable operation, high performance and energy saving. The ash may be used as the admixture of cement, decreasing environmental pollution and increasing economic benefit.

CFB boiler can burn various fuels, such as soft coal, anthracite coal, lean coal, lignite, gangue, sludge, petroleum coke, biomass (wood chip, bagasse, straw, palm husk, rice husk, etc.)

CFB boilers are specially designed and optimized for applications to produce medium and high pressure steam or hot water with rated evaporation capacity from 35 to 440 ton/hr and rated pressure from 3.82 to 9.8 MPa. The design heat efficiency of CFB boilers is up to 87~90%.

Features:

1. Burning efficiency reaches 95%-99%, high burning rate, heat efficiency above 87%.

2. Energy-saving, high efficiency, high flexibility of fuel, which can satisfy the burning of many kinds of fuel.

3. Limestone can be added in bed material during burning process reacts with SO2 of flue formulates sulphate, desulphuration can satisfy environment protection

4. Reasonable wind distribution and low temperature or furnace can control formulation of NOx and really reach environment protection.

5. Big adjusting range load can be adjusted to 30-110%.

6. High automatic control makes boilers running safely and economically in long term.

7. Adopt upper exhaust high temperature cyclone separated device, high collection of bed material.

8. High heat transfer efficiency, high ability of overload.

Application:

CFB boilers are widely used for power generation in chemical industry, paper making industry, textile industry, food and drinking industry, pharmaceuticals industry, sugar refinery, tire factory, palm oil factory, alcohol plant, etc.

| Technical Data of CFB Hot Water Boiler | ||||||||||||

| Model | Rated Thermal Power (MW) | Rated Output Pressure (MPa) | Rated Output Temperature (°C) | Rated Input Temperature (°C) | Fuel Consumption (kg/h) | Flue Gas Temperature (°C) | Primary Air Temperature (°C) | Secondary Air Temperature (°C) | Ratio of Primary Air to Secondary Air | Width (incl. platform) (mm) |

Depth (incl. platform) (mm) |

Height of drum centerline (mm) |

| QXX29-1.25/150/90-M | 29 | 1.25 | 150 | 90 | 9489 | 150 | 150 | 150 | 1:1 | 9400 | 13250 | 22000 |

| QXX58-1.6/150/90-M | 58 | 1.6 | 150 | 90 | 18978 | 150 | 150 | 150 | 1:1 | 11420 | 15590 | 31000 |

| QXX116-1.6/150/90-M | 116 | 1.6 | 150 | 90 | 37957 | 150 | 180 | 170 | 1:1 | 14420 | 20700 | 35000 |

| Remark | 1. Fuel particle is ≤10mm, and limestone particle is ≤2mm. 2. Design efficiency is 88%. 3. Desulphurization efficiency is 90%. 4. Heat efficiency and fuel consumption is calculated by LHV 12670KJ/Kg(3026kcal/kg). |

|||||||||||

| Specifications of CFB Steam Boiler | ||||||||||||

| Model | Rated Evaporation Capacity (t/h) | Rated Steam Pressure (MPa) | Feed Water Temperature (°C) | Rated Steam Temperature (°C) | Fuel Consumption (kg/h) | Flue Gas Temperature (°C) | Primary Air Temperature (°C) | Secondary Air Temperature (°C) | Ratio of Primary Air to Secondary Air | Width (incl. platform) (mm) |

Depth (incl. platform) (mm) |

Height of drum centerline (mm) |

| TG35-3.82-M | 35 | 3.82 | 150 | 450 | 8595 | 150 | 150 | 150 | 1:1 | 9200 | 13555 | 25000 |

| TG75-3.82-M | 75 | 3.82 | 150 | 450 | 18418 | 150 | 150 | 150 | 1:1 | 11420 | 15590 | 32500 |

| TG75-5.29-M | 75 | 5.29 | 150 | 485 | 18321 | 150 | 150 | 150 | 1:1 | 11420 | 15590 | 32500 |

| TG130-3.82-M | 130 | 3.82 | 150 | 450 | 31924 | 150 | 180 | 170 | 1:1 | 14420 | 20700 | 35000 |

| TG130-5.29-M | 130 | 5.29 | 150 | 485 | 31756 | 150 | 180 | 170 | 1:1 | 14420 | 20700 | 35000 |

| TG130-9.8-M | 130 | 9.8 | 215 | 540 | 30288 | 150 | 200 | 200 | 1:1 | 14010 | 20800 | 37000 |

| TG220-3.82-M | 220 | 3.82 | 150 | 450 | 54025 | 150 | 200 | 200 | 1:1 | 16700 | 23200 | 41500 |

| TG220-5.29-M | 220 | 5.29 | 150 | 485 | 53742 | 150 | 200 | 200 | 1:1 | 16700 | 23200 | 41500 |

| TG220-9.8-M | 220 | 9.8 | 215 | 540 | 51256 | 150 | 200 | 200 | 1:1 | 16700 | 23200 | 41500 |

| TG440-13.7-M | 440 | 13.7 | 250 | 540 | 102520 | 150 | 200 | 200 | 1:1 | 29000 | 32000 | 50050 |

| Remark | 1. TG steam boilers are suitable for all types of fuels. 2. Fuel particle is ≤10mm, and limestone particle is ≤2mm. 3. Design efficiency is 88%. 4. Desulphurization efficiency is 90%. 5. Heat efficiency and fuel consumption is calculated by LHV 12670KJ/Kg(3026kcal/kg). |

|||||||||||

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for Factory For Pulverized Coal Fired Boiler Pdf – CFB Coal Fired Boiler – Taishan Group , The product will supply to all over the world, such as: Bangladesh , Cyprus , Czech , We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We are able to also provide you with no cost samples to meet your needs. Best efforts will be produced to offer you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our products and enterprise. lot more, you'll be able to come to our factory to find out it. We will constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. Please really feel absolutely free to make contact with us for small business and we believe we will share the top trading practical experience with all our merchants.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.