Low MOQ for Coal Fired Boiler Operation - DHL Coal Fired Boiler – Taishan Group

Low MOQ for Coal Fired Boiler Operation - DHL Coal Fired Boiler – Taishan Group Detail:

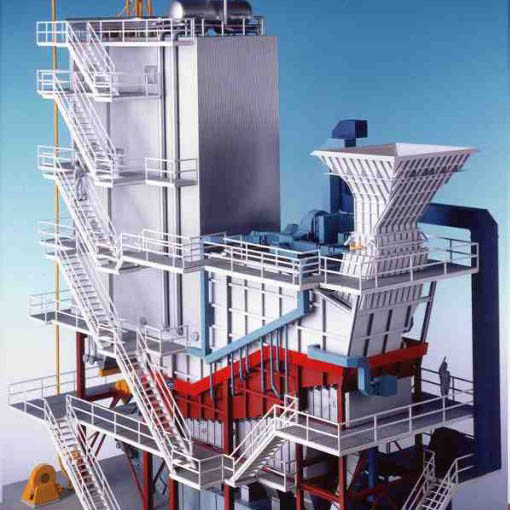

DHL Coal Fired Boiler

Product Description

DHL series boiler is single drum horizontal chain grate bulk boiler. The burning part adopts flake chain grate to match with high-quality auxiliary equipment and perfect automatic control system, which ensures safe, stable and efficient operation of boiler.

DHL series coal fired boilers are designed and optimized for applications to produce low, medium and high pressure steam or hot water with rated evaporation capacity from 10 to 65 ton/hr and rated pressure from 1.25 to 9.8 MPa. The design heat efficiency of DHL coal boilers is up to 81~82%.

Features:

1. High efficiency, low fuel consumption; low operating costs

2. High safety level, panel-type heating surface in the furnace, furnace heated evenly.

3. Improve the furnace temperature field to ensure safe operation of the boiler

4. Reasonable flue gas speed, heating surface without ash deposition and no abrasion, under the condition of no soot-blowing, the boiler can work full-load, high-efficiency and safety in long term.

5. The big and tall boiler furnace can be designed according to the different fuel to improve the burning rate of fuel and remove black smoke.

6. All independent loop and reasonable coal boiler injected circulation are specially designed and adopted for the hot water boilers. The medium speed in loop of heat surface is higher than national standard.

7. Environmental protection effect is good, use multi-level dust removal, reduce exhaust gas concentration, Ringelmann blackness is less than 1.

Application:

DHL series coal fired boilers are widely used in chemical industry, paper making industry, textile industry, food industry, pharmaceuticals industry, heating industry, construction industry.

| Technical Data of DHL Coal Fired Hot Water Boiler | ||||||||||

| Model | Rated Thermal Power (MW) | Rated Output Pressure (MPa) | Rated Output Temperature (°C) | Rated Input Temperature (°C) | Radiation Heating Area (m²) | Convection Heating Area (m²) | Air Preheater Heating Area (m²) | Active Grate Area (m²) | Flue Gas Temperature (°C) | Installation Dimension (mm) |

| DHL29-1.6/130/70-AII | 29 | 1.6 | 130 | 70 | 195 | 640 | 275 | 34.4 | 153 | 12600x11200x15000 |

| DHL46-1.6/130/70-AII | 46 | 1.6 | 130 | 70 | 296 | 786 | 624 | 57.2 | 150 | 14600x13600x15000 |

| DHL58-1.6/130/70-AII | 58 | 1.6 | 130 | 70 | 361 | 1181 | 804 | 70.9 | 159 | 13200x15000x17000 |

| DHL64-1.6/130/70-AII | 64 | 1.6 | 130 | 70 | 371 | 1556 | 1450 | 78.27 | 147 | 13800x15000x17000 |

| DHL70-1.6/130/70-AII | 70 | 1.6 | 130 | 70 | 474 | 1488 | 901 | 87.8 | 150 | 14200x17000x17600 |

| Remark | 1. DHL coal fired hot water boilers are suitable for all types of coals. 2. Design thermal efficiency is 82~84%. | |||||||||

| Technical Data of DHL Coal Fired Steam Boiler | ||||||||||||||

| Model | Rated Evaporation Capacity (t/h) | Rated Steam Pressure (MPa) | Feed Water Temperature (°C) | Rated Steam Temperature (°C) | Radiation Heating Area (m2) | Slag Screen Heating Area (m2) | Superheater Heating Area (m2) | Convection Heating Area (m2) | Economizer Heating Area (m2) | Air Preheater Heating Area (m2) | Active Grate Area (m2) | Coal Consumption (kg/h) | Flue Gas Temperature (℃) | Installation Dimension (mm) |

| DHL35-3.82-AII | 35 | 3.82 | 105 | 450 | 152 | 35.4 | 271 | 630 | 693.3 | 31.4 | 6310 | 143 | 14500x10500x14900 | |

| DHL65-1.6-AII | 65 | 1.6 | 105 | 204 | 421.4 | 1085.1 | 826 | 410.3 | 63 | 7792 | 152 | 18000x15300x15000 | ||

| DHL65-3.82-AII | 65 | 3.82 | 150 | 450 | 293 | 59 | 510 | 923 | 1179 | 61.34 | 10940 | 160 | 16500x13400x16000 | |

| Remark | 1. Design thermal efficiency is 81~82%. 2. Heat efficiency and coal consumption is calculated by LHV 19845KJ/Kg (4740kcal/kg). | |||||||||||||

Product detail pictures:

Related Product Guide:

We intention to see quality disfigurement within the creation and supply the ideal support to domestic and overseas buyers wholeheartedly for Low MOQ for Coal Fired Boiler Operation - DHL Coal Fired Boiler – Taishan Group , The product will supply to all over the world, such as: Sevilla , Slovak Republic , moldova , We supply skilled service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound items with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ??customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.