OEM Customized Biomass Fired Thermal Oil Boiler - CFB Biomass Boiler – Taishan Group

OEM Customized Biomass Fired Thermal Oil Boiler - CFB Biomass Boiler – Taishan Group Detail:

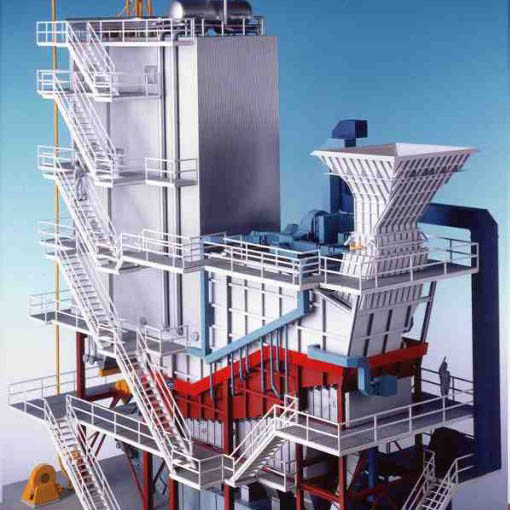

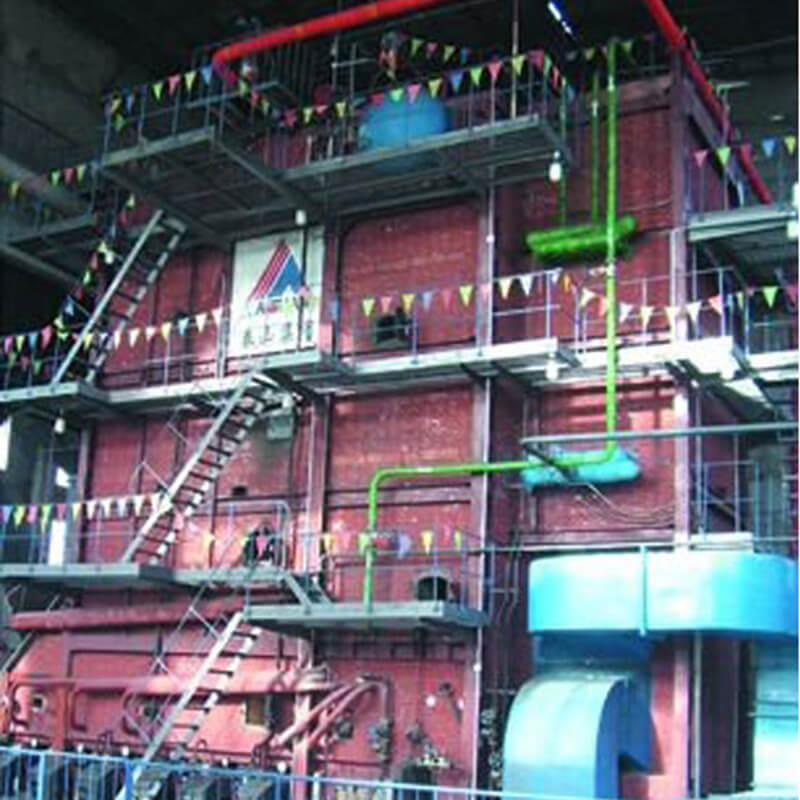

CFB Biomass Boiler

Product Description

CFB (Circulating Fluidized Bed) biomass boiler is energy saving, environmentally friendly and efficient. CFB biomass boiler can burn various biomass fuels, such as wood chip, bagasse, straw, palm husk, rice husk, etc. CFB biomass boiler features larger heating area, low bed temperature combustion, low bed pressure technology, staged combustion, efficient separation, SNCR and SCR denitration, low excess air coefficient, reliable anti-wear technology, mature sealing technique, and overtemperature non-coking technology.

CFB biomass boilers can produce medium and high pressure steam with rated evaporation capacity of 35-130 ton/h and rated pressure of 3.82-9.8 MPa. The designed thermal efficiency is up to 87~90%.

Features:

1. Smaller air leakage coefficient reduces flue gas amount and resistance, a corresponding reduction in ID fan power consumption.

2. Low bed pressure technology reduces the material layer height, fluidization height, wind chamber pressure, and primary air power consumption.

3. Low bed temperature technology (low-temperature combustion) control the flue gas temperature, grade air supply, reduce NOX amount.

4. Larger heating surface ensures the boiler output and meets the 110% load requirements.

5. High temperature cyclone separation circulating combustion system; furnace chamber and wind chamber and connected by membrane water wall.

Application:

CFB boilers are widely used in the power generation in chemical industry, paper making industry, textile industry, food and drinking industry, pharmaceuticals industry, sugar refinery, tire factory, palm oil factory, alcohol plant, etc.

| Technical Data of CFB Biomass Steam Boiler | ||||||||

| Model | Rated Evaporation Capacity (t/h) | Rated Steam Pressure (MPa) | Feed Water Temperature (°C) | Rated Steam Temperature (°C) | Fuel Consumption (kg/h) | Primary Air Fan | Secondary Air Fan | Induced Air Fan |

| TG35-3.82-SW | 35 | 3.82 | 150 | 450 | 8680 | Q=30911m3/h P=14007Pa |

Q=25533m3/h P=8855Pa |

Q=107863m3/h P=5200Pa |

| TG75-3.82-SW | 75 | 3.82 | 150 | 450 | 18400 | Q=52500m3/h P=15000Pa |

Q=34000m3/h P=9850Pa |

Q=200000m3/h P=5500Pa |

| TG75-5.29-SW | 75 | 5.29 | 150 | 485 | 18800 | Q=52500m3/h P=15000Pa |

Q=34000m3/h P=9850Pa |

Q=200000m3/h P=5500Pa |

| TG75-9.8-SW | 75 | 9.8 | 215 | 540 | 19100 | Q=52500m3/h P=15000Pa |

Q=34000m3/h P=9850Pa |

Q=200000m3/h P=5500Pa |

| TG130-3.82-SW | 130 | 3.82 | 150 | 450 | 29380 | Q=91100m3/h P=16294Pa |

Q=59000m3/h P=9850Pa |

Q=2x152000m3/h P=5500Pa |

| TG130-5.29-SW | 130 | 5.29 | 150 | 485 | 29410 | Q=91100m3/h P=16294Pa |

Q=59000m3/h P=9850Pa |

Q=2x152000m3/h P=5500Pa |

| TG130-9.8-SW | 130 | 9.8 | 215 | 540 | 29500 | Q=91100m3/h P=16294Pa |

Q=59000m3/h P=9850Pa |

Q=2x152000m3/h P=5500Pa |

| Remark | 1. Design efficiency is 88%. | |||||||

Product detail pictures:

Related Product Guide:

To continually enhance the management technique by virtue of your rule of "sincerely, great faith and high-quality are the base of company development", we widely absorb the essence of similar merchandise internationally, and continuously build new merchandise to meet the demands of customers for OEM Customized Biomass Fired Thermal Oil Boiler - CFB Biomass Boiler – Taishan Group , The product will supply to all over the world, such as: Hamburg , Malaysia , Bahrain , As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to provide our clients sincerely with qualified products, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!