OEM manufacturer Biomass Boiler - DHW Biomass Boiler – Taishan Group

OEM manufacturer Biomass Boiler - DHW Biomass Boiler – Taishan Group Detail:

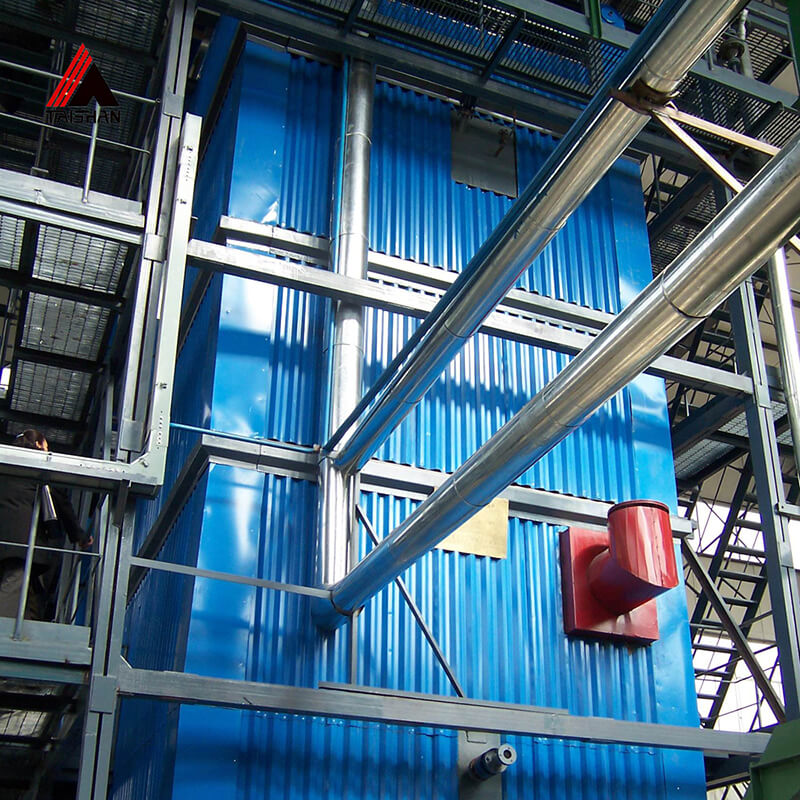

DHW Biomass Boiler

Product Description

DHW series biomass boiler is single drum horizontal inclined reciprocating grate boiler, the reciprocating grate’s angle of inclination is 15°. The furnace is membrane wall structure, furnace outlet has slag-cooling tubes, and furnace outlet flue gas temp is lowered to below 800℃, lower than the melting point of fly ash, to prevent the fly ash from slagging on the superheater. After the slag-cooling tubes, there are high-temperature superheater, low-temperature superheater, economizer and air preheater, there is spray type desuperheater between two superheaters. The flue gas temperature after air preheater is 160℃.

DHW series biomass boiler can generate low pressure steam with rated evaporation capacity of 10-65 ton/h and rated pressure of 1.25-9.8 MPa. The designed thermal efficiency is up to 82%.

Features:

1. Since biomass fuel is apt to slagging, reciprocating grate’s ceaseless movement avoids slagging.

2. Biomass fuel features small density and small ash particle, which is apt to flow with the flue gas, so we design high furnace and small flow velocity.

3. Secondary air ensures that the fuel’s standing time in the furnace makes the fuel burn out in the furnace.

4. The arch is used to strengthen the mixture of airflow in the furnace and organize the thermal radiation and hot flue gas flow in the furnace.

5. To avoid soot formation, the pitch of convection heating surface shall be in-line arrangement.

6. The convection bank has acoustic wave soot blower, which may remove the soot, and cleaning door is equipped.

Application:

DHW series biomass boilers are widely used in the electricity production in various industries, such as chemical industry, paper making industry, textile industry, food industry, pharmaceuticals industry, heating industry, construction industry, etc.

| Technical Data of DHW Biomass Steam Boiler | ||||||||||

| Model | Rated Evaporation Capacity (t/h) | Rated Steam Pressure (MPa) | Feed Water Temperature (°C) | Rated Steam Temperature (°C) | Radiation Heating Area (m2) | Convection Heating Area (m2) | Economizer Heating Area (m2) | Air Preheater Heating Area (m2) | Active Grate Area (m2) | Flue Gas Temperature (℃) |

| DHW15-2.5-400-SW | 15 | 2.5 | 105 | 400 | 132.7 | 131.3 | 265.8 | 122.6 | 15.2 | 158 |

| DHW30-4.1-385-SW | 30 | 4.1 | 105 | 385 | 168.5 | 150.9 | 731.8 | 678.3 | 23.8 | 141 |

| DHW35-3.82-450-SW | 35 | 3.82 | 105 | 450 | 152 | 306.4 | 630 | 693.3 | 31.4 | 160 |

| DHW38-3.5-320-SW | 38 | 3.5 | 105 | 320 | 238.6 | 623.6 | 470.8 | 833.5 | 41.8 | 160 |

| DHW40-5.0-360-SW | 40 | 5 | 105 | 360 | 267.8 | 796.4 | 1024.5 | 591 | 43.6 | 156 |

| DHW50-6.7-485-SW | 50 | 6.7 | 105 | 485 | 368 | 847.5 | 951.1 | 1384 | 58.4 | 150 |

| Remark | 1. Design thermal efficiency is 82%. | |||||||||

Product detail pictures:

Related Product Guide:

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for OEM manufacturer Biomass Boiler - DHW Biomass Boiler – Taishan Group , The product will supply to all over the world, such as: New York , Mecca , Spain , We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.