OEM Manufacturer Biomass Coal Fired Steam Boiler - CFB Coal Fired Boiler – Taishan Group

OEM Manufacturer Biomass Coal Fired Steam Boiler - CFB Coal Fired Boiler – Taishan Group Detail:

Product Description

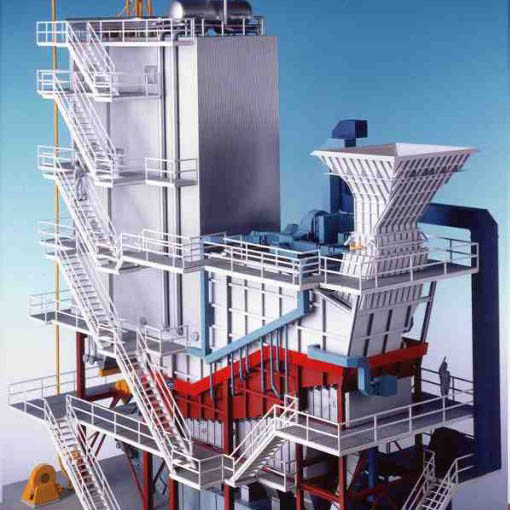

CFB boiler (Circulating Fluidized Bed Boiler) features good coal adaptation, safe and reliable operation, high performance and energy saving. The ash may be used as the admixture of cement, decreasing environmental pollution and increasing economic benefit.

CFB boiler can burn various fuels, such as soft coal, anthracite coal, lean coal, lignite, gangue, sludge, petroleum coke, biomass (wood chip, bagasse, straw, palm husk, rice husk, etc.)

CFB boilers are specially designed and optimized for applications to produce medium and high pressure steam or hot water with rated evaporation capacity from 35 to 440 ton/hr and rated pressure from 3.82 to 9.8 MPa. The design heat efficiency of CFB boilers is up to 87~90%.

Features:

1. Burning efficiency reaches 95%-99%, high burning rate, heat efficiency above 87%.

2. Energy-saving, high efficiency, high flexibility of fuel, which can satisfy the burning of many kinds of fuel.

3. Limestone can be added in bed material during burning process reacts with SO2 of flue formulates sulphate, desulphuration can satisfy environment protection

4. Reasonable wind distribution and low temperature or furnace can control formulation of NOx and really reach environment protection.

5. Big adjusting range load can be adjusted to 30-110%.

6. High automatic control makes boilers running safely and economically in long term.

7. Adopt upper exhaust high temperature cyclone separated device, high collection of bed material.

8. High heat transfer efficiency, high ability of overload.

Application:

CFB boilers are widely used for power generation in chemical industry, paper making industry, textile industry, food and drinking industry, pharmaceuticals industry, sugar refinery, tire factory, palm oil factory, alcohol plant, etc.

| Technical Data of CFB Hot Water Boiler | ||||||||||||

| Model | Rated Thermal Power (MW) | Rated Output Pressure (MPa) | Rated Output Temperature (°C) | Rated Input Temperature (°C) | Fuel Consumption (kg/h) | Flue Gas Temperature (°C) | Primary Air Temperature (°C) | Secondary Air Temperature (°C) | Ratio of Primary Air to Secondary Air | Width (incl. platform) (mm) |

Depth (incl. platform) (mm) |

Height of drum centerline (mm) |

| QXX29-1.25/150/90-M | 29 | 1.25 | 150 | 90 | 9489 | 150 | 150 | 150 | 1:1 | 9400 | 13250 | 22000 |

| QXX58-1.6/150/90-M | 58 | 1.6 | 150 | 90 | 18978 | 150 | 150 | 150 | 1:1 | 11420 | 15590 | 31000 |

| QXX116-1.6/150/90-M | 116 | 1.6 | 150 | 90 | 37957 | 150 | 180 | 170 | 1:1 | 14420 | 20700 | 35000 |

| Remark | 1. Fuel particle is ≤10mm, and limestone particle is ≤2mm. 2. Design efficiency is 88%. 3. Desulphurization efficiency is 90%. 4. Heat efficiency and fuel consumption is calculated by LHV 12670KJ/Kg(3026kcal/kg). |

|||||||||||

| Specifications of CFB Steam Boiler | ||||||||||||

| Model | Rated Evaporation Capacity (t/h) | Rated Steam Pressure (MPa) | Feed Water Temperature (°C) | Rated Steam Temperature (°C) | Fuel Consumption (kg/h) | Flue Gas Temperature (°C) | Primary Air Temperature (°C) | Secondary Air Temperature (°C) | Ratio of Primary Air to Secondary Air | Width (incl. platform) (mm) |

Depth (incl. platform) (mm) |

Height of drum centerline (mm) |

| TG35-3.82-M | 35 | 3.82 | 150 | 450 | 8595 | 150 | 150 | 150 | 1:1 | 9200 | 13555 | 25000 |

| TG75-3.82-M | 75 | 3.82 | 150 | 450 | 18418 | 150 | 150 | 150 | 1:1 | 11420 | 15590 | 32500 |

| TG75-5.29-M | 75 | 5.29 | 150 | 485 | 18321 | 150 | 150 | 150 | 1:1 | 11420 | 15590 | 32500 |

| TG130-3.82-M | 130 | 3.82 | 150 | 450 | 31924 | 150 | 180 | 170 | 1:1 | 14420 | 20700 | 35000 |

| TG130-5.29-M | 130 | 5.29 | 150 | 485 | 31756 | 150 | 180 | 170 | 1:1 | 14420 | 20700 | 35000 |

| TG130-9.8-M | 130 | 9.8 | 215 | 540 | 30288 | 150 | 200 | 200 | 1:1 | 14010 | 20800 | 37000 |

| TG220-3.82-M | 220 | 3.82 | 150 | 450 | 54025 | 150 | 200 | 200 | 1:1 | 16700 | 23200 | 41500 |

| TG220-5.29-M | 220 | 5.29 | 150 | 485 | 53742 | 150 | 200 | 200 | 1:1 | 16700 | 23200 | 41500 |

| TG220-9.8-M | 220 | 9.8 | 215 | 540 | 51256 | 150 | 200 | 200 | 1:1 | 16700 | 23200 | 41500 |

| TG440-13.7-M | 440 | 13.7 | 250 | 540 | 102520 | 150 | 200 | 200 | 1:1 | 29000 | 32000 | 50050 |

| Remark | 1. TG steam boilers are suitable for all types of fuels. 2. Fuel particle is ≤10mm, and limestone particle is ≤2mm. 3. Design efficiency is 88%. 4. Desulphurization efficiency is 90%. 5. Heat efficiency and fuel consumption is calculated by LHV 12670KJ/Kg(3026kcal/kg). |

|||||||||||

Product detail pictures:

Related Product Guide:

Our enterprise since its inception, often regards solution excellent as enterprise life, continually strengthen output technology, enhance product high quality and continually strengthen organization total high-quality administration, in strict accordance using the national standard ISO 9001:2000 for OEM Manufacturer Biomass Coal Fired Steam Boiler - CFB Coal Fired Boiler – Taishan Group , The product will supply to all over the world, such as: Orlando , kazan , Slovenia , As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.